Laser Welding Machines: Continuously advancing technological developments in the industry have also led to significant transformations in joining processes. If we consider laser welding machines, it stands out as an innovative technology that provides faster, more precise and effective joining compared to traditional welding methods. In this blog post, we will examine what laser welding machines are, their working principles and usage areas.

Working Principle of Laser Welding Machines:

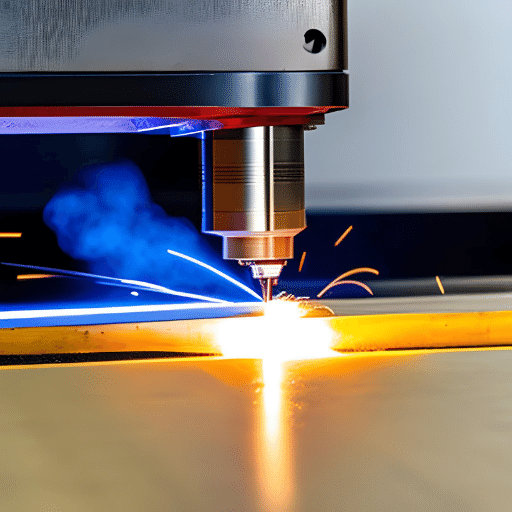

Laser welding machines perform the process of joining materials using a high-intensity laser beam. The laser beam, concentrated at the point where the materials to be welded come into contact, melts the surface of the material and joins the two parts. As a result of this process, the material is melted and cooled. Laser welding machines use precise focusing systems and timing mechanisms to control the welding process.

Advantages of Laser Welding Machines:

Laser welding machines have many advantages and are preferred over traditional welding methods:

- Precision: Laser welding machines work with high precision and enable thin, complex parts to be joined. This is a great advantage in the manufacture of precision components.

- Speed and Efficiency: Laser welding machines work quickly and complete the joining job in a single operation. In particular, this saves time and increases efficiency in production processes.

- Energy Control: Laser welding machines precisely control the amount and intensity of energy. This minimizes undesirable effects on the material and optimizes welding results.

- Clean and Durable Welds: Laser welding machines create clean and durable welds due to the low heat impact. This allows for reduced post-weld work and increased part quality.

Usage Areas of Laser Welding Machines:

Laser welding machines are widely used in many industries. Here are some uses:

- Automotive: Especially in the Automotive industry, laser welding machines are used to join parts such as vehicle bodies, exhaust systems and wheels. This enables lightweight and robust welded components to be produced.

- Electronics: In the electronics industry, laser welding machines are used for joining precision electronic components. Thanks to the lower heat effect compared to the soldering process, the quality and durability of the parts increase.

- Medicine: Laser welding machines are used in the production of medical devices and implants. This ensures sterile and reliable joining.

- Metalworking: Laser welding machines are widely used for joining metal parts. It is especially effective in joining delicate and thin parts.

Conclusion:

Laser welding machines offer innovative technology for fast, precise and efficient joining processes. These machines, which have many advantages over traditional welding methods, are widely used in many sectors. Finally, in industries where laser welding machines are used, it becomes possible to produce more reliable and quality products.

You can view our Laser Welding Machines HERE.

For detailed information on the subject, you can contact us on our WhatsApp line. Get Information with WhatsApp